CHARACTERISTICS

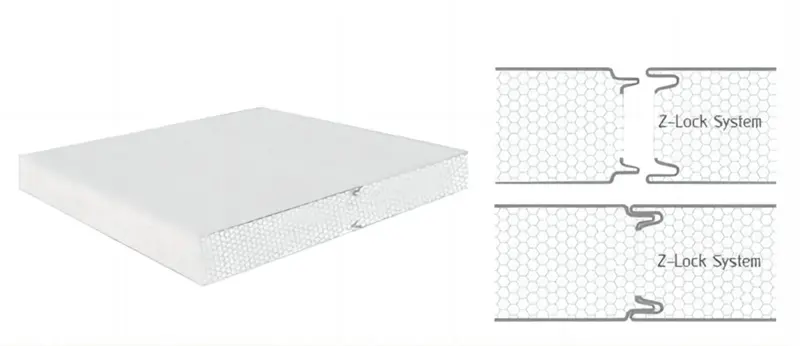

EPS = Good Heat Insulation

Z-Lock EPS Sandwich Panel with EPS foam cores meet the strictest heat insulation

requirements, while also complying with the required insulation properties and maintaining a good bearing capacity.

▲EPS insulation core

▲Sound Insulation

▲Vertical or horizontal installation

▲Standard lengths are from 2 m to 10 m (max. 12 m)

▲Thickness of insulation core 50, 75, 100, 125, 150, and 200 mm

DESCRIPTION

Z-Lock EPS Sandwich Panels are composed of 3 layers, the external and internal is two dyed Galvanized or Aluminum corrugated plates, and core high density EPS foam. Thanks to their properties the panels may be applied in object that require very high fire resistance, EPS sandwich panel is the most effective acoustic materials used on construction.

Take the 50mm thick Z-Lock EPS sandwich panel for example and the panel can absorb the sound over 30 db/m2.Widely used in the steel structure factory building, activities room, roof, wall, air clean room ceiling and partition.

SPECIFICATIONS

| Panel Thickness | 40mm,50mm,75mm,100mm |

| Type of Base Steel Sheet | Hot-dip galvanized,Al-Zn coated |

| Core Material Density | 6-20[kg/m³] |

| Type of Sheet Coating | PVDF,HDP,SMP,PE |

| Thickness of Steel Sheet | 0.4-0.7mm |

| Standard Length | According to the customer's request |

| Cover Width | 960mm |

| Fire Resistance | Non-flammable |

CHARACTERISTICS

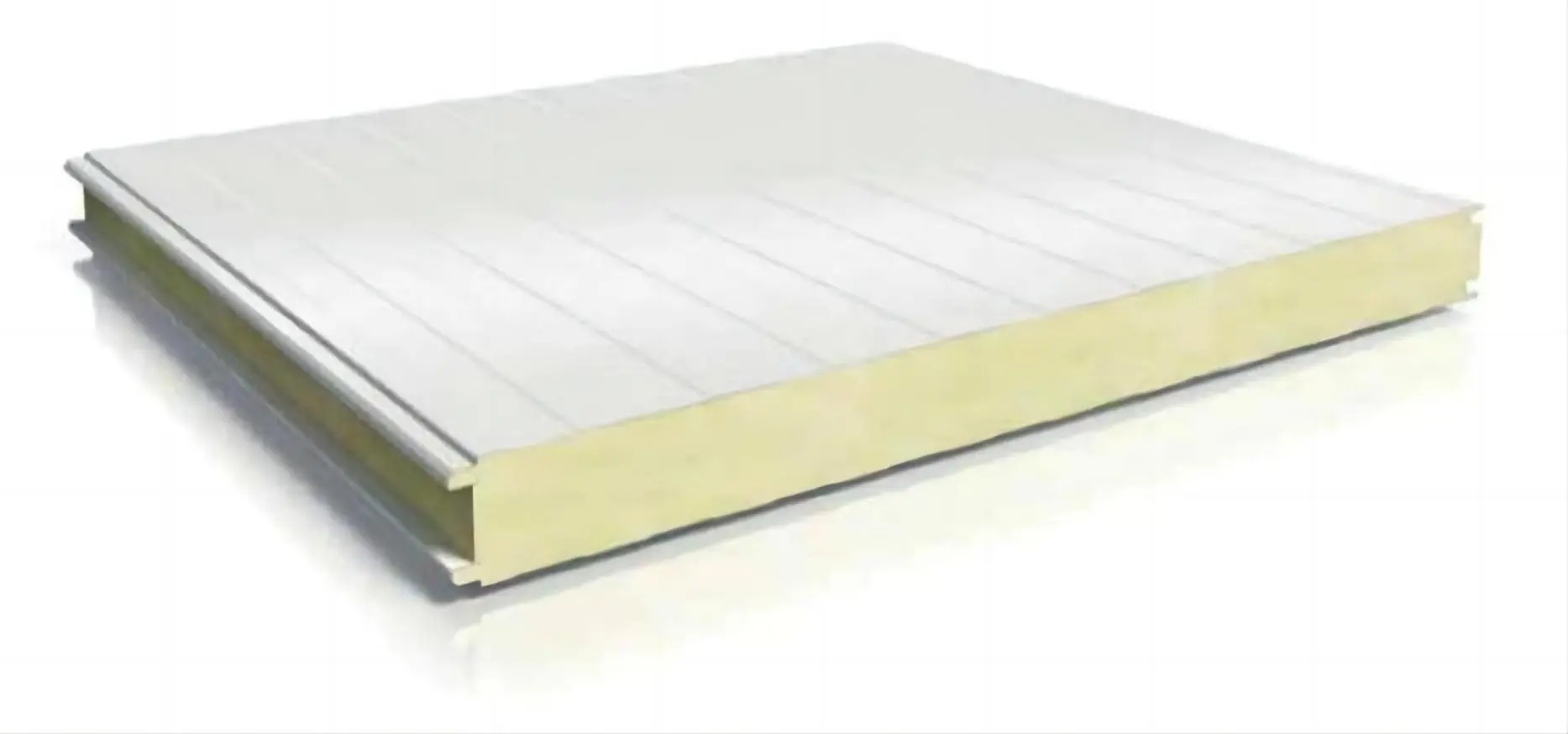

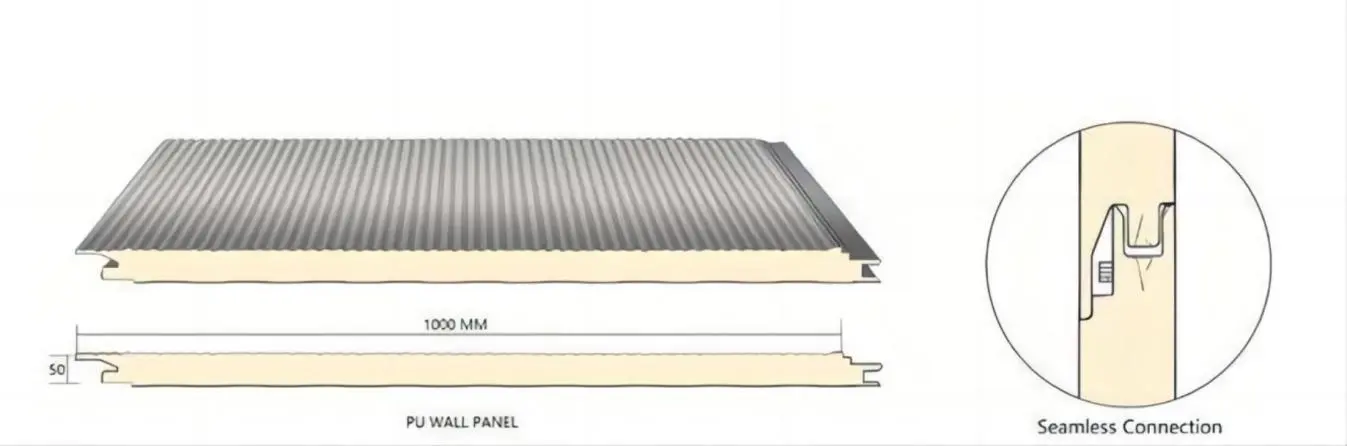

PU (Polyurethane) = Good Heat Insulation

PU Sandwich Panels with polyurethane foam cores meet the strictest heat insulation requirements, while also complying with the required insulation properties and maintaining a good bearing capacity.

▲ PU insulation core

▲ High fire resistance

▲ Vertical or horizontal installation

▲ Standard lengths are from 2 m to 10 m (max. 12 m)

▲ Thickness of insulation core 50, 75, 100, 125, 150, and 200 mm

DESCRIPTION

PU Sandwich Panels are composed of 3 layers, the external and internal is two dyed Galvanized or Aluminum corrugated plates, and core high density POLYURETAHE foam. Thanks to their properties the panels may be applied in object that require very high fire resistance, PU sandwich panel is the most effective acoustic materials used on construction.

Take the 50 mm thick PU sandwich panel for example and the panel can absorb the sound over 30 db/m2.Widely used in the steel structure factory building, activities room, roof, wall, air clean room ceiling and partition.

SPECIFICATIONS

| Panel Thickness | 40mm, 50mm, 75mm, 100mm |

| Standard Facings | Steel sheet coated with polyester paint, 25μm Hign Zinc sheet with Zn 50-Zn 180g Stainless steel |

| Core Material Density | 40 [kg/m³] |

| Thermal Conductivity | 0.022 [W/mK] |

| Acoustic Insulation | 30 [dB] |

| Standard Length | 2m-12m |

| Effective width | 1000mm |

| Fire resistance | Non-flammable |

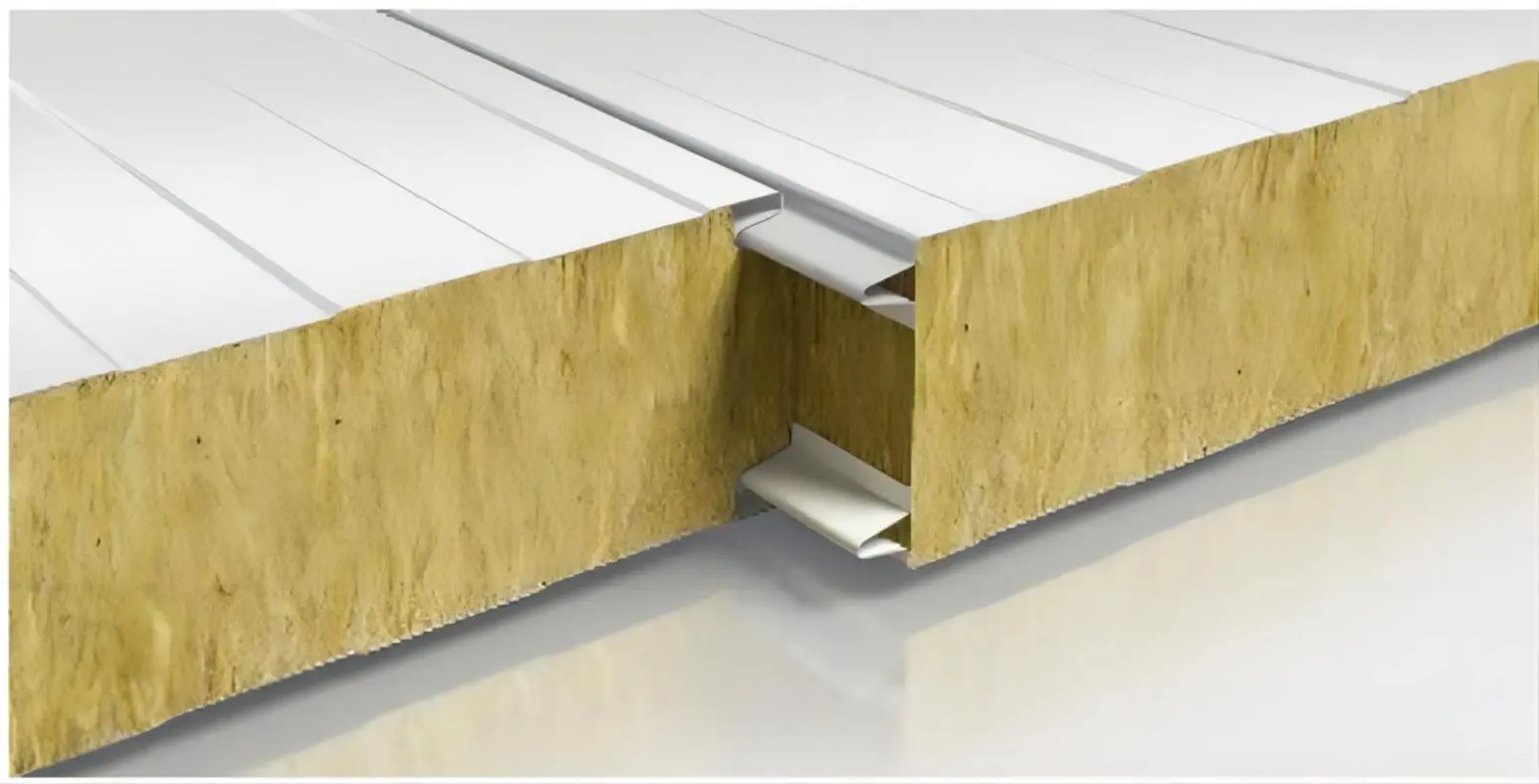

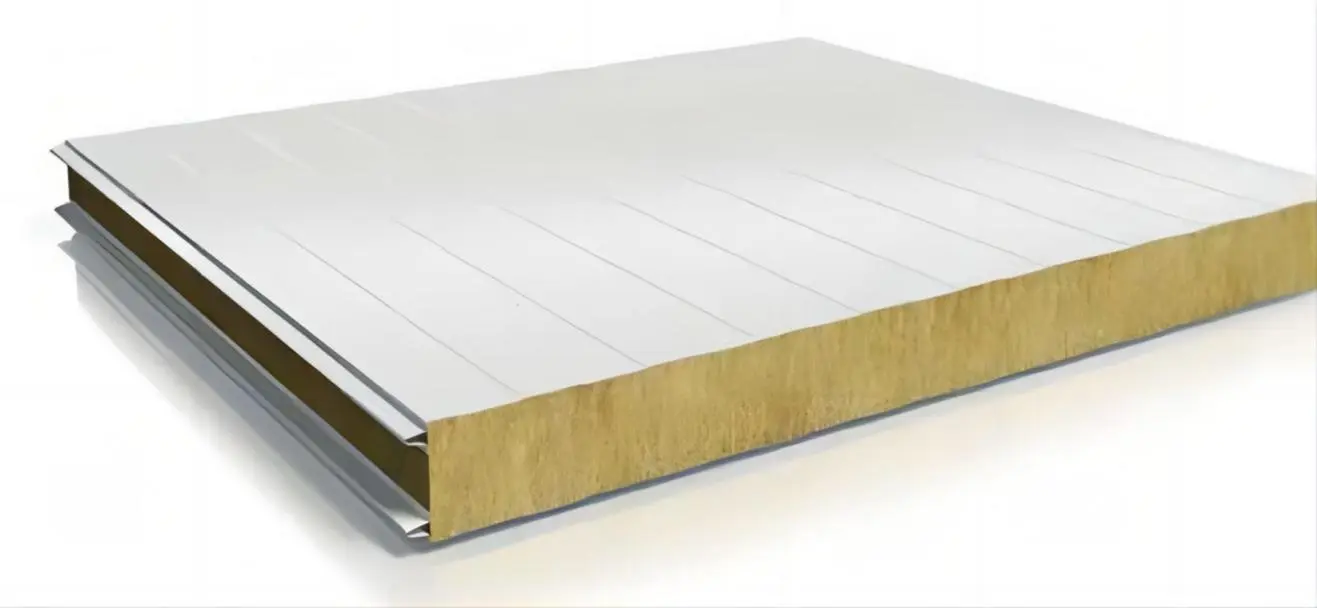

CHARACTERISTICS

Rock wool = high fire resistance

The rock wool insulating core has high fire resistance and excellent sound insulation. Wall sandwich panels with a mineral wool insulation core offer high fire resistance and thermal insulation properties.

▲ Rock wool insulation core

▲ High fire resistance

▲ Vertical or horizontal installation

▲ Standard lengths are from 2 m to 10 m (max. 12 m)

▲ Thickness of insulation core 50, 75, 100, 125, 150, and 200 mm

DESCRIPTION

Rock wool Sandwich Panels are composed of 3 layers, the external and internal is two dyed Galvanized or Aluminum corrugated plates, and core high density Rock wool (Mineral Wool). Thanks to their properties the panels may be applied in object that require very high fire resistance, rock wool sandwich panel is the most effective acoustic materials used on construction.

Take the 50mm thick rock wool sandwich panel for example and the panel can absorb the sound over 30 db/m2.Widely used in the steel structure factory building, activities room, roof, wall, air clean room ceiling and partition.

SPECIFICATIONS

| Panel Thickness | 50mm, 75mm, 100mm |

| Standard Facings | Steel sheet coated with polyester paint, 25μm High Zinc sheet with Zn 50-Zn180g Stainless steel |

| Core Material [kg/m³] | Density 100/120 |

| Thermal Conductivity [W/m2K] | 0.043 |

| Acoustic Insulation [dB] | 27 |

| Standard Length [m] | 2m-12m |

| Effective Width [mm] | 1000mm |

| Fire Resistance | Non-flammable |

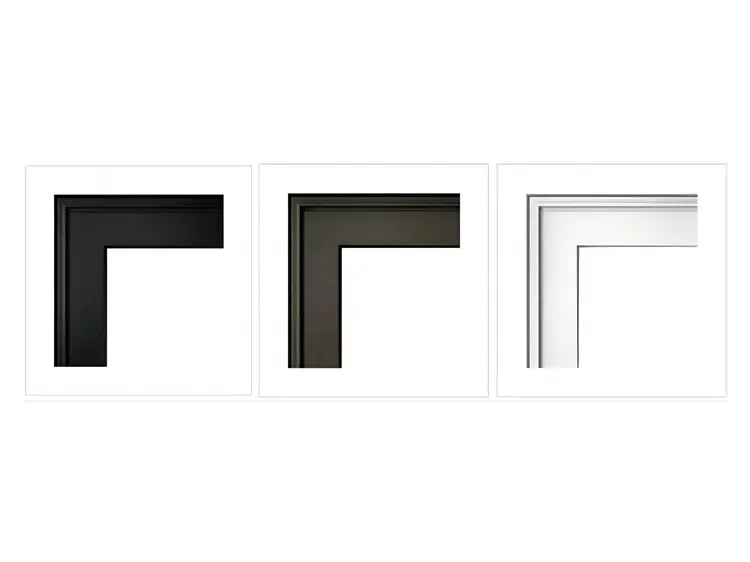

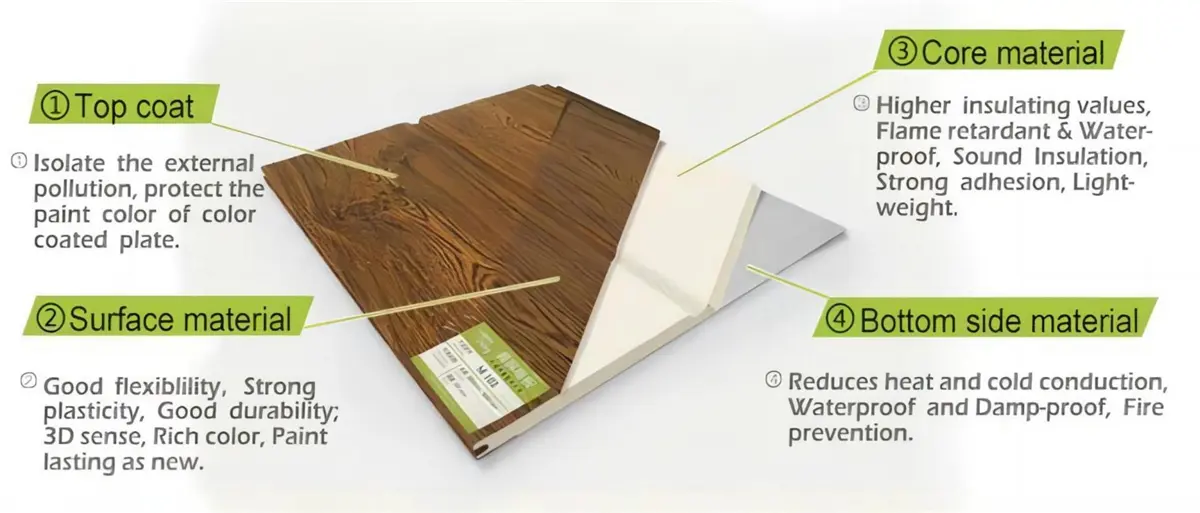

ADVANTAGES of PU foam siding wall cladding panel:

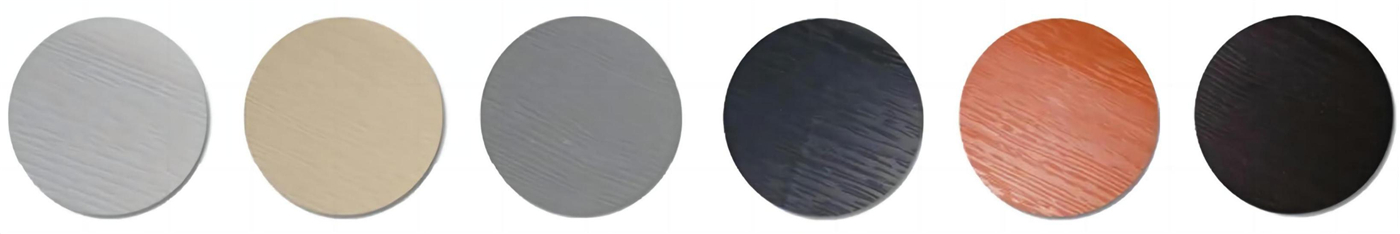

1. The rich selection of textures and colors meet different decoration requirements,giving the city and the buildings a new look.

2. PU foam is the most advanced and eco-friendly insulation material in the world. With the help of the back aluminum foil, the thermal preservation effect achieves the best.

3. The unique structure prevents heat loss in winter. Meanwhile, it reduces the heat of the summer sunshine.

4. Lightweight makes the installation easy.

5. The installation process is clean and tidy without any noise and dust, construction waste.

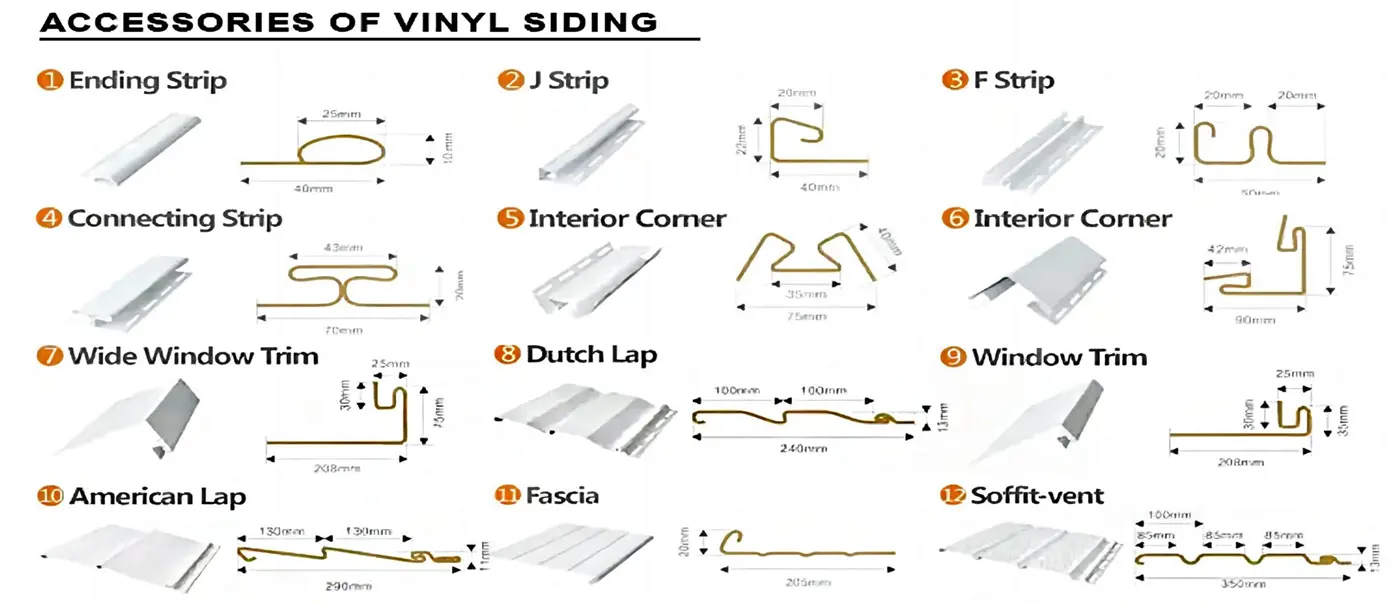

6. Different selections of accessories meet different effects.

7. High quality and stable performance.

PU foam siding wall cladding panel consists of three layers: the top material is special aluminum-zinc coated metal board, the core material is rigid high-density Polyurethane foaming with fire-retardant treatment, and the back material is fiber foil paper.

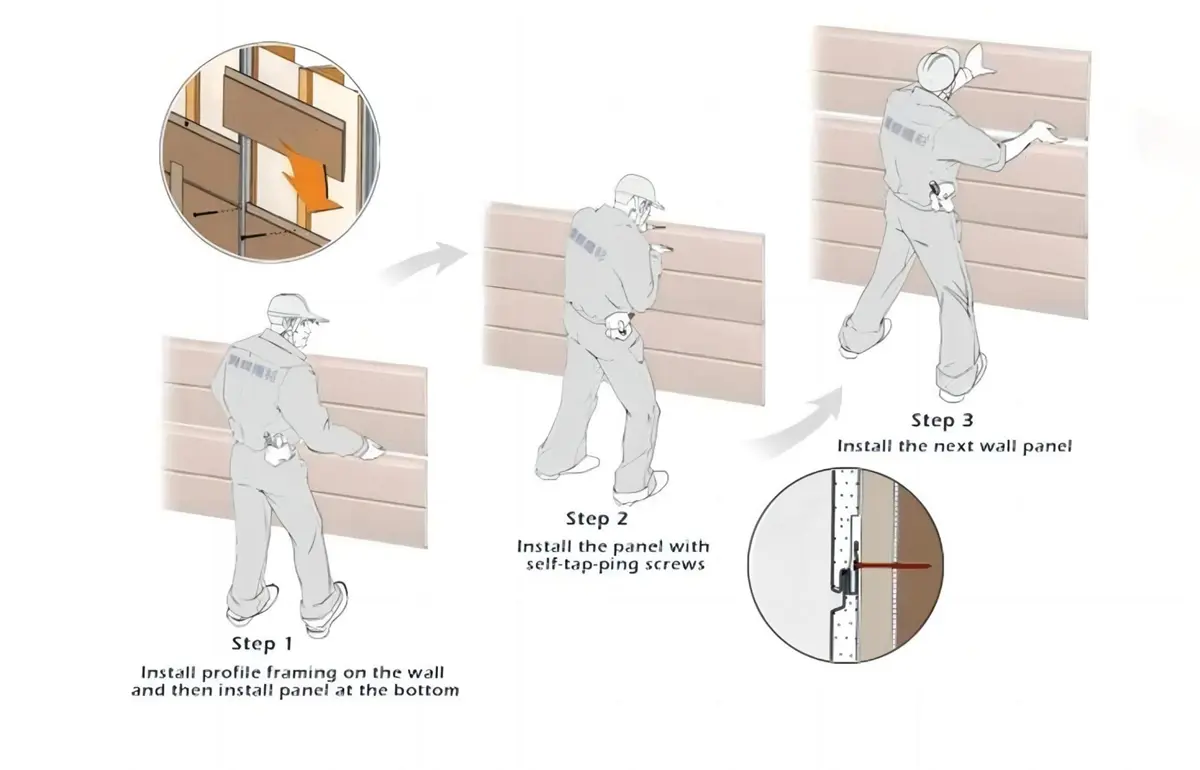

Installation Method

PVC panel represents the modern coating solution alternative to traditional methods and materials, with a wide range of realistic and touch-sensitive effects.

PVC panels are produced with composite materials that do not deform, are antiseptic and are not attacked by fungus or micro organisms. Essential feature that differentiates them from wooden products for a total absence of maintenance. Waterproofing and the possibility of being washed with a pressure washer guarantee one of the main advantages of the PVC cladding. With a natural design, PVC cladding are made of composite materials, a guarantee of quality and sustainability thanks to the non-use of additives containing heavy metals, phthalates and SVHC substances. The use of water-based paints allows us to offer a more resistant and safer panel. Water-based paints allow us to comply with the rules for the reduction of emissions of solvents in the atmosphere, also protecting the health of the operator and guaranteeing excellent aesthetic and qualitative results.

Laminate Floor

The sub-floor is usually plywood coated with anti-corrosive paint, or cement fiberboard. The surface floor can be chosen from laminate floor, PVC floor leather, SPC floor, solid wood floor and bamboo floor.

Laminate flooring is affordable and looks just like wood, tile or stone, without the cost, maintenance or wear and tear. It’s also scratch resistant, water resistant and the click-lock design makes it easy to install.

PVC Floor

If you want the look and feel of Laminated / hardwood floors, PVC / Vinyl plank flooring is great option. PVC flooring comes in many different patterns and styles in wood / carpet / grass finish. PVC plank flooring has all of the design benefits of real wood floors, but it is more durable, easier to clean, easier to install.

010203

Kitchen Cabinet

Is a leading professional manufacturer and service provider of A-grade cranes. The company has

introduced advanced crane technology from Europe and integrates crane research and development,

manufacturing, sales, installation, and service. We mainly produce European style cranes, double

beam bridge cranes, single beam bridge cranes, gantry cranes, suspension cranes, jib cranes, and

universal wire rope electric hoists; Other non-standard cranes and various specialized

components for cranes,